In the world of manufacturing, efficiency, and precision are everything. Today’s market demands high-quality products, quick turnarounds, and lean operations, all while facing rising operational costs and increased global competition. But achieving these goals takes work. Many manufacturers need help with outdated systems, limited visibility into real-time production data, and the challenge of ensuring consistent quality control. As production lines and supply chains become more complex, staying efficient without sacrificing quality becomes a daily challenge. This is where Global IT can help manufacturers keep up and truly excel.

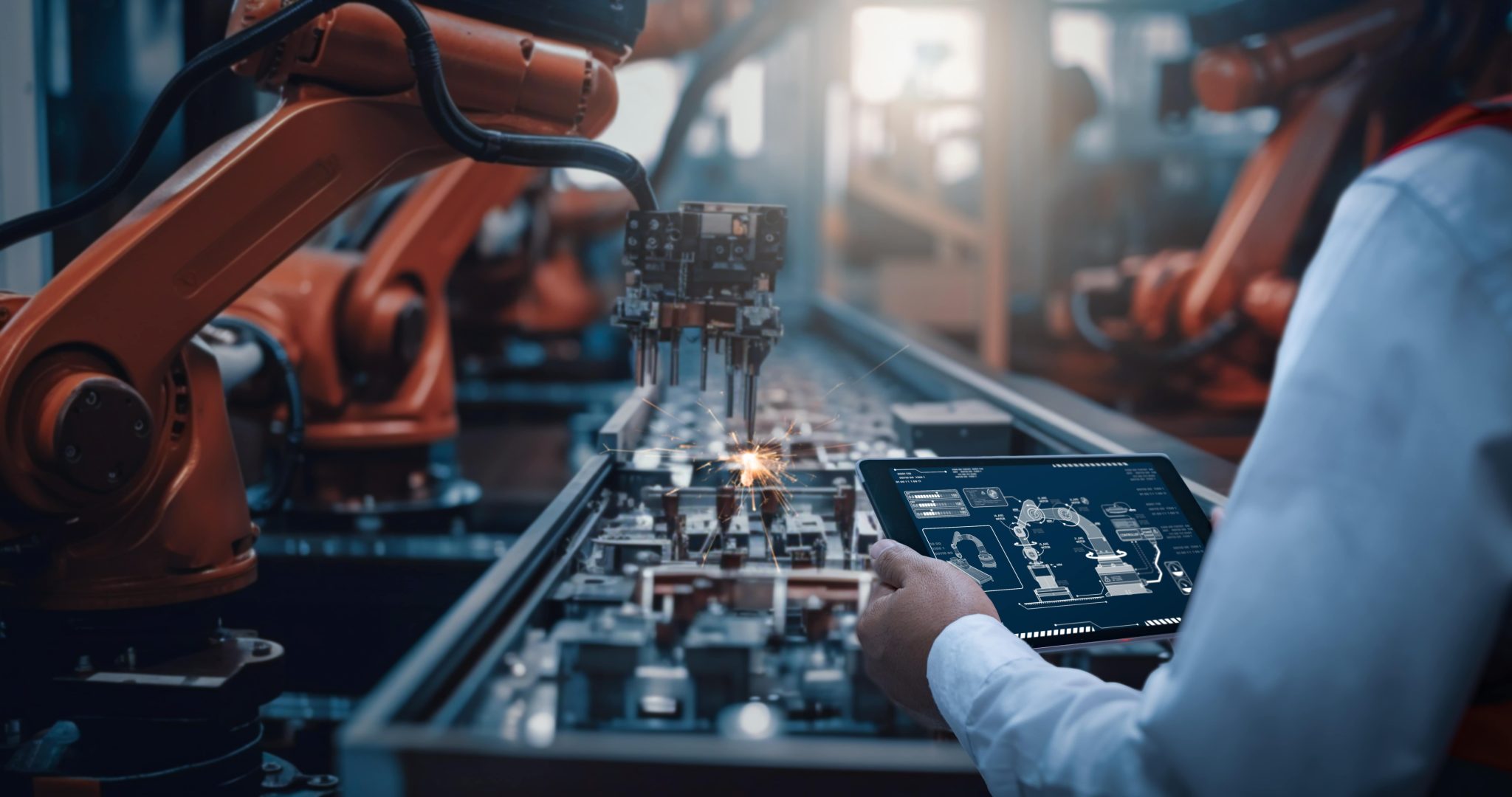

Imagine the potential if your factory could predict equipment failures before they happened or if your team could spot quality issues in real time instead of after production. You can transform these goals into achievable outcomes by adopting smart manufacturing technologies like AI, IoT, and big data analytics.

Global IT offers the expertise and technology solutions to make this possible, guiding you step-by-step as you integrate new systems into existing workflows. As the leader driving your business forward, you have the power to make these changes; Global IT is here to ensure you have the right tools, training, and support to succeed in this new digital manufacturing era.

Smart manufacturing integrates digital systems like IoT, AI, and big data analytics to enhance factory processes. These technologies connect machines, sensors, and software, allowing real-time monitoring and control. As a result, factories can predict issues, reduce waste, and keep production lines running smoothly.

Global IT helps manufacturers adopt these tools by providing strategies and solutions tailored to their unique needs. With the right approach, companies can modernize operations without disrupting existing workflows.

The Internet of Things (IoT) enables factories to collect and analyze data from various devices and systems. This data offers insights into equipment performance, product quality, and energy usage.

AI boosts manufacturing by automating decision-making and analyzing large volumes of data quickly.

Data analytics tools allow manufacturers to gain valuable insights from operational data, guiding more informed decision-making.

Adopting smart manufacturing brings significant benefits, but it also presents challenges. Here’s how Global IT addresses these common obstacles:

By applying IT-driven strategies, manufacturers worldwide are achieving remarkable outcomes:

These success stories demonstrate how IT-backed solutions can address specific industry pain points.

Manufacturers continue to push boundaries with technologies like digital twins, which create virtual replicas of production systems for testing and optimization. Machine learning and robotics advances will drive even greater efficiency, with IT solutions enabling manufacturers to adapt to market demands quickly.

Global IT remains committed to guiding companies through these advancements, ensuring they stay agile and responsive in a fast-paced industry.

Global IT offers comprehensive solutions for businesses looking to capitalize on smart manufacturing, from initial consultations to full-scale integrations. Our team tailors strategies that fit each client’s needs. With expertise in cybersecurity, IoT, and AI, we ensure manufacturers are prepared for every step of their digital transformation.

To explore how Global IT can support your smart manufacturing journey, schedule a personalized consultation by emailing us at info@globalit.com.